Transport, wrap, stack

The G1015 roller wrapper makes it possible to perform the cycles "Transport", "Wrap" and "Stack" with one single machine. And, thanks to its exceptionally sturdy and compact design, it is guaranteed to have a long service life. The wrapper is suitable for both front and rear installation. Customers can choose from an extensive selection of loader attachments.

Control

The G1015 wrapper comes standards with the easy-to-use STANDARD program control that includes an electronic joystick. All functions can also be executed directly at the control housing of the machine – which comes in handy when the operator needs to change the film. Better still, additional connections make it possible to use the wrapper's program control to also actuate the hydraulic upper linkage.

Wrapping arm with film stretching unit

The wrapping arm is equipped with a film stretching unit that can accommodate 750 mm rolls of film. The three patented plastic rollers provide for perfectly uniform stretching. What is more, the rollers are not sensitive to temperature. This helps save film and guarantees firmly wrapped bales. The quick-release system makes it possible to change empty rolls quickly and effortlessly.

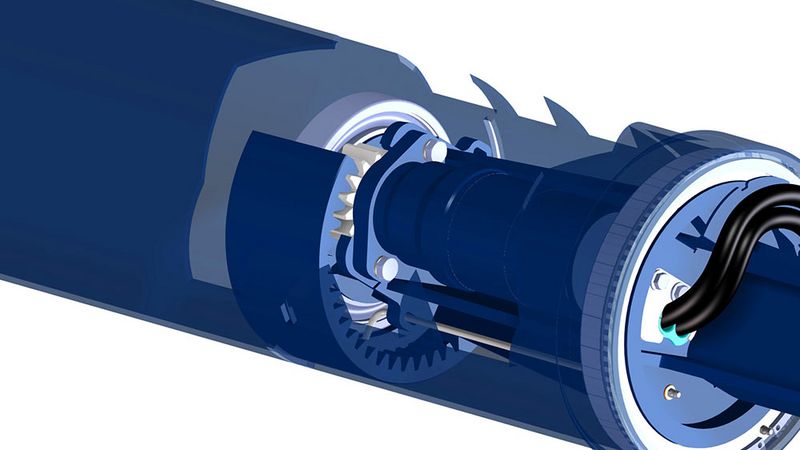

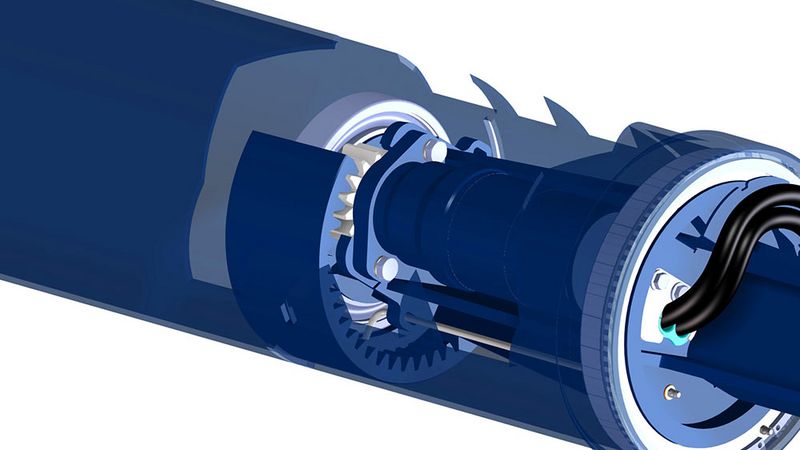

Hydraulic cylinders and hydraulic motors

The hydraulic cylinders housed in the base frame of the wrapper and the hydraulic motors are safely protected. The hydraulic motors are mounted on the inside of the rollers.

Rollers

The large-size rollers of the G1050 wrapper guarantee that even the heaviest bales can be wrapped with flawless ease. Powered separately from one another, the rollers stretch the film around the bales in a uniform movement.

Hydraulic upper linkage

The pitch of the wrapper can be adjusted continuously and with perfect ease thanks to the hydraulic upper linkage. Optional connections for the upper linkage make it possible to control the upper linkage with the wrapper’s program control.

Automatic film cutting and holding system

The stainless steel knife guarantees that the film will be cut cleanly and precisely. At the same time, the film is fixed in place by the cutter lever. Shortly after the wrapping process begins, the standard float position ensures that the film will unwind easily.

Additional equipment

A host of additional equipment options allow the user to customize and expand the machine to their individual needs.